December 2025 Vol. 80 No. 12

Features

Inside Sempra’s 72-mile pipeline with 18 major trenchless crossings

By David Paul Bearden Jr., Reilly Schoo, Jennie Hart, HDR

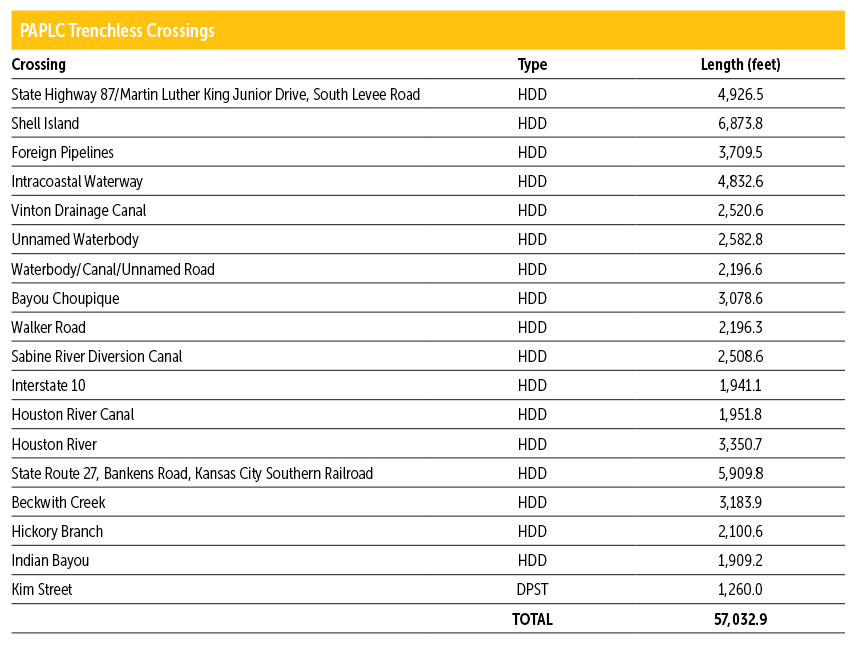

(UI) — Sempra Infrastructure’s Port Arthur Pipeline Louisiana Connector Project (PAPLC) includes approximately 72 miles of 42-inch-diameter pipeline and 18 trenchless crossings that total more than 57,000 feet, making it a significant trenchless project worthy of recognition. HDR partnered with Sempra Infrastructure as the trenchless detailed design, geotechnical engineering and construction consultant for the project.

Other important project contributors included Doyle Land Services for land rights and right-of-way, Onward Resources for pipeline design and survey, general contractor Troy Construction, and HDD subcontractors MAXX HDD, Michels, HardRock Infrastructure Services, and North Country Directional Drilling. The crossings include 17 horizontal directional drills (HDDs) and one direct steerable pipe thrust (DPST), installed by subcontractor The Trenchless Company.

HDR designed the trenchless crossing installations to fit within the permitted workspaces, including 13 water (bayou, canal, river, and creek), one foreign pipeline and five road or major highway crossings, including Interstate 10, a vital interstate in south Louisiana. The longest HDD crossing was water-to-water in Sabine Lake, spanning 6,874 feet. The shortest was 1,909 feet.

PAPLC trenchless crossings

The Kim Street installation, the project’s only DPST installation, had limited space to work within. The crossing was originally permitted as open-cut construction. However, Sempra Infrastructure chose to go under the property with the DPST so the landowner could continue business operations during construction.

With a workspace already approved for open-cut construction, HDR’s design team strategically configured the DPST crossing and 42-inch-diameter pipe stringing and assembly to fit the limited available footprint. The limited workspace was fitted with crane mats, maximizing disturbance limits, pipe fabrication and equipment staging area as much as possible.

Without other options, the large, heavy pipe was staged to the side of the DPST in seven sections rather than behind the DPST launch pit in a single pipe string, as is typical. The construction team utilized extra support equipment, including cranes and excavators, to handle and reposition pipe strings one section at a time for welding before going downhole.

Geotechnical investigation

The HDR team performed an extensive subsurface geotechnical investigation for the PAPLC project, including 72 bores totaling 10,075 feet of drilling. To prepare designs and supplemental project-specific documentation to meet Federal Energy Regulatory Commission (FERC) HDD guidelines and criteria for permitting, HDR carefully evaluated pipeline alignment that required bores on land and over water, and comprehensively explored the subsurface conditions for lengthy trenchless crossings.

Investigation supported detailed designs and constructability evaluations, including site-specific hydraulic fracture and inadvertent returns analyses for each HDD and DSPT. HDR’s work was critical to evaluating trenchless feasibility, as well as providing necessary documentation for permitting agencies to approve trenchless construction methods.

Gaining regulatory approval

Sempra Infrastructure primarily collocated the pipeline within existing rights-of-way of other infrastructure to minimize environmental disruptions and streamline development. The project received FERC authorization in April 2019. Changes in the pipeline route were required prior to construction due to landowner requests, encroachment by third-party facilities or development, modifications recommended by regulators, construction optimization, and other measures to reduce impacts to natural areas, including wetlands and waters of the United States.

HDR assisted Sempra Infrastructure with an Amendment to the FERC-authorized project, which was submitted in 2023. Modifications specific to trenchless crossings, intended for minimizing changes to the pipeline plans originally permitted, included:

- Changing three waterbody crossings from open cut to HDD

- Combining multiple HDDs into a single HDD

- Converting one portion of open cut between two HDDs to all HDD

- Eliminating one HDD location

HDD alignments were also altered to avoid conflicts with deeper potential canal depths. These route modifications changed environmental effects, including a net decrease of 10.6 acres of construction impacts and 9.5 acres of operational impacts to wetlands. In addition to the Amendment preparation, HDR also performed cultural resources field surveys and coordinated with the Texas State Historical Preservation Office and U.S. Fish and Wildlife Service.

Sempra Infrastructure received FERC’s Order Approving Amendment in May 2024. The full pipeline project went to construction in November 2024 after receiving FERC’s Notice to Proceed in October 2024.

Complex trenchless construction

Construction of the trenchless crossings started in March 2025 and ended earlier than forecasted, in September 2025. Seventy-two miles of construction were divided into two spreads. The first, more southern half of the alignment included approximately 34 miles in marshland and water. The second was approximately 38 miles of more upland terrain.

HDR monitored trenchless construction onsite, providing real-time recommendations in the field to address construction and crossing-specific challenges, helping avoid construction delays. The team’s strong geotechnical investigation and thoroughly considered trenchless design program prepared the construction team for site and subsurface conditions, minimizing construction and installation challenges. Each contractor had pertinent information for execution, helping deliver successful installations for each crossing.

The 42-inch-diameter pipe was Grade X-70 for the comprehensive pipeline, featuring variable wall thicknesses (Class I: 0.600-inch, Class II: 0.720-inch, and Class III: 0.864-inch) to meet diverse terrain and pressure demands. All trenchless crossings met Class III requirements.

Handling the larger-diameter pipeline with heavy wall pipe (0.864-inch) required proper planning and additional equipment in some instances, making some of the crossings more challenging than others. This was especially true for the water-to-water and land-to-water crossings where the contractors were challenged by the marine environment and in-water construction.

Construction teams also dealt with significant impacts from weather, including frequent periods of downtime because of localized lightning strikes. All crew members were alert and responsive to their surroundings, routinely monitoring the weather conditions and maintaining safe working conditions.

FERC also required 20-foot sound walls at nine locations to trap HDD-related construction noise and maintain acceptable noise levels. The project team also worked hard to maintain environmental standards by:

- Performing thorough water testing

- Preparing and executing extensive drill plans with drilling fluid management procedures

- Installing primary and secondary silt fencing for strong right-of-way discipline in many cases

Although the project’s construction contractors experienced weather delays, stringent environmental measures and other challenges, trenchless installations were completed ahead of the forecasted end date.

Successfully installed PAPLC

The PAPLC 42-inch-diameter pipeline extends through Cameron, Calcasieu and Beauregard Parishes of Louisiana and into Jefferson County, Texas. It will transport natural gas to the Port Arthur Liquefied Natural Gas (LNG) facility under development in Port Arthur, Texas. With a maximum allowable operating pressure of 1,440 psi, the PAPLC is designed to supply 2 billion standard cubic feet per day (BSCFD) of feed gas to meet the LNG process demand for Port Arthur liquefaction trains with the highest degree of reliability.

The Port Arthur LNG project, including PAPLC, is expected to generate thousands of jobs, have a positive impact on the economy, and provide access to reliable US natural gas to markets worldwide. The project’s trenchless crossings exceeded all success indicators by finishing ahead of schedule and staying under budget while setting new benchmarks for responsible infrastructure development.

Comments