December 2025 Vol. 80 No. 12

Tech Tips

ASTM F1216 updates reshape pressure pipe design for CIPP rehabilitation

(UI) — Since its initial release in 1989, ASTM F1216 has undergone 14 revisions. Perhaps the most widely utilized and referenced industry standard for pipeline rehabilitation, it includes processes, performance requirements, and guidelines that translate to other technologies beyond cured-in-place pipe (CIPP) installed by the inversion method, for which F1216 was originally developed.

Design concepts included in non-mandatory Appendix X1 were originally established based on classical pipe theory, applied to homogeneous CIPP liners that are unbonded to the host pipe and adapted to account for lost pipe continuity. Design checks for CIPP installed within gravity-flow pipelines and low-pressure sewers with varying levels of host pipe deterioration were provided.

Pressure pipe design checks were originally intended to account for buried sewers in surcharge conditions due to heavy rain events or force mains operating at low internal pressures, generally up to 10 psi. However, limitations on their use are well documented in Appendix X1, which—combined with a lack of other industry pressure pipe design methodologies—led to their widespread adoption across the pipeline rehabilitation industry without a full understanding of how to apply theory to practice.

Evolution of hole spanning design

Design checks for hole spanning in pressure pipes were developed by Joe Aggarwal in 1983 and incorporated into the first release of F1216 in 1989. This approach was based on plate bending theory published by R.J. Rourke and was intended to analyze CIPP’s ability to span a circular hole as a flat plate with a fixed edge.

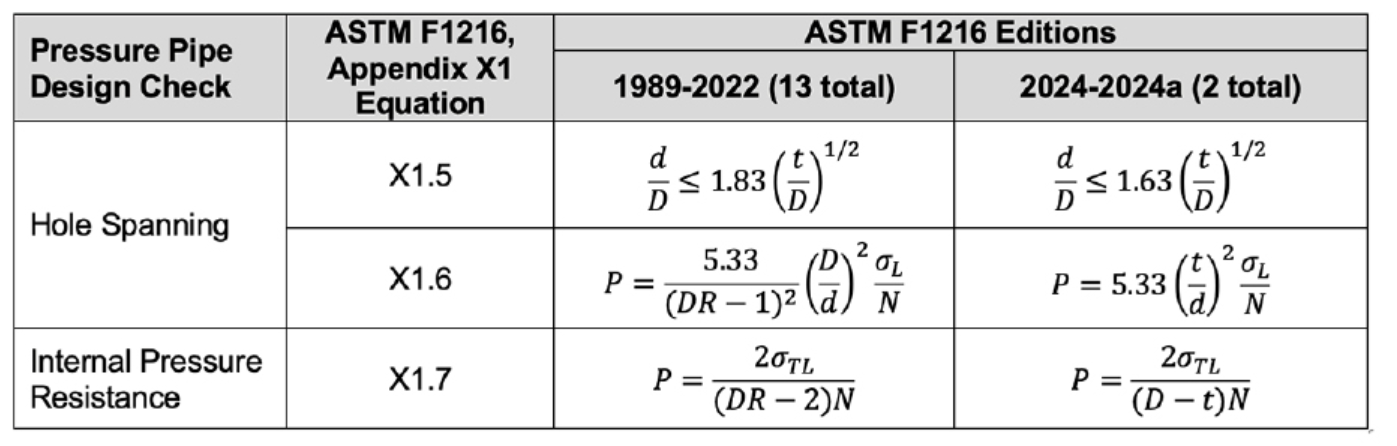

Subsequent review of Aggarwal’s original derivations revealed a transcription error in Equation X1.5 involving the utilization of a constant of 1.83 in lieu of the correct value of 1.63. Although this variance seems consequential at face value, sensitivity analysis revealed that differences in calculated results can be significant. In addition, previous versions of Equations X1.6 and X1.7 utilized dimension ratio (DR), or the ratio of outside diameter to wall thickness, which is not applicable to anisotropic composites such as reinforced CIPP, and inside diameter measurements for CIPP instead of its mean diameter. The change to mean diameter results in a slight reduction in calculated internal pressure resistance, with increasing diameters and wall thicknesses. Modifications to Equations X1.5, X1.6, and X1.7 were made and reflected in the 2024 and 2024a revisions of ASTM F1216, as summarized in the table below.

Pressure pipe design considerations

In addition to pressure pipe design checks, ASTM F1216 requires that certain gravity pipe design equations be satisfied. For a partially deteriorated pressure pipe, resistance to hydrostatic buckling must also be checked using Equation X1.1. For fully deteriorated pressure pipe, Equations X1.1, X1.3, and X1.4 also must suffice.

Equation X1.3 conservatively assumes that all surcharge loads (soil, groundwater, and dead loads) are transferred to the CIPP liner, while X1.4 is a pipe stiffness check that applies to handling and installation of new pipe and is irrelevant to liner design. For gravity pipe design, Equation X1.4 can control, sometimes egregiously, and has been rightly removed from other relevant CIPP design approaches including AWWA M28 and F2019 (UV cure GRP-CIPP) and F3541 (CIPP sectional repairs), but remains in F1216. Also, Equation X1.3 wrongly assumes groundwater to the top of pipe instead of the invert. This has also been addressed in F2019 and F3541 but has yet to be corrected in F1216.

Structural stability and applicability

It is important to note that pressure pipe systems that are structurally compromised or unstable—as defined by ASTM F1216 for a fully deteriorated host pipe—are not good candidates for CIPP lining and are generally repaired or replaced in kind using traditional methods such as dig-and-replace or pipe bursting. Pressure pipes identified for lining are predominantly structurally sound but may exhibit infiltration/exfiltration and some slight out-of-roundness due to wear, minor abrasion, and/or surface corrosion.

In this scenario, CIPP is designed to resist groundwater pressures or vacuum when out of service.

Standards alignment and industry progress

From an industry standards standpoint, significant strides have been made in recent years to advance pressure pipelining design, with the publication of the AWWA Committee Report, Structural Classifications of Pressure Pipe Linings, in 2019, followed by AWWA CIPP Standard C623 in 2022, and the evolving C623 design appendix, which is currently being developed through the AWWA Pipeline Rehabilitation Committee. These advancements are helping bring normative design practice, acceptance criteria for CIPP, and other close-fit liners used in the structural renewal of pressure pipes into closer alignment with real-world performance.

Comments