November 2025 Vol. 80 No. 11

Features

Stopping hydrate plugs: How operators can pinpoint pipeline blockages and restore flow

By Stuart Mitchell

(UI) — Businesses operating within the midstream sector of the oil and gas industry have an exhaustive list of obstacles to contend with. Some, like challenging weather or evolving regulations, are external. Other obstacles, though, are strictly internal – including your approach to asset integrity and management.

How are you ensuring the stability and structural longevity of your pipeline? Are you confident that practices are in place to certify that systems are protected and that any obstructions or deposits can be quickly and efficiently dealt with – without completely sidelining productivity?

One of the most stubborn and problematic adversaries in pipeline maintenance is the hydrate plug. Speak to operators, and they’ll tell you they are all too familiar with the persistence of hydrate plugs and the constant battle with the physics that causes them. A naturally occurring blockage in pipelines carrying wet natural gas, NGLs, or crude, hydrate plugs form when under-pressure hydrocarbon cross paths with free water in high-pressure or low-temperature conditions.

Offshore operators often encounter them in subsea lines exposed to frigid seawater, while onshore systems may see hydrates form during winter operations or in long, under-insulated stretches.

Although they resemble ice, these hydrates are stronger, denser and can form rapidly inside pipelines – creating a headache in the blink of an eye. When left unchecked, they can accumulate into full bore plugs that bring operations to a premature halt.

Adding insult to injury, the presence of a hydrate plug represents more than just lost production.

Challenge of hydrate plugs

Hydrates are notoriously difficult to predict and virtually impossible to visually confirm without excavation, costly non-destructive examination or intrusive inspection. Even after confirming their location, any attempts to dislodge or depressurize them can lead to sudden and risk-inducing gas releases, with the potential of uncontrolled pressure surges risking a catastrophic rupture.

Naturally, this combination of uncertainty over their appearance and location, the risk of removing them, and the cost of the entire process makes hydrate plugs one of the most difficult challenges in flow assurance and pipeline integrity.

Some of the main challenges hydrates present to operators include:

- Uncertainty of location. Hydrates do not leave obvious surface clues to inform areas to target. Instead, blockages may be suspected miles from their actual location, making excavation or remediation a high-wire, needle-in-a-haystack exercise.

- High-risk removal. Even when finally locating the hydrate, heating, depressurization or chemical injection strategies can be hazardous. A sudden release of trapped product as a plug breaks free can lead to violent decompression.

- Production downtime. Even smaller deposits or partial restrictions can cut throughput, while full plugs stop operations cold, leading to lost revenue and costly mitigation campaigns.

- Operational inefficiency. Without precise data on the location of hydrates, responsible crews may waste days chasing after false positives along the miles of pipeline, even going so far as to attempt interventions that miss the true blockage point.

Hydrate plugs and other blockages are a natural part of pipeline life. For decades, the industry has leaned on a mix of chemical inhibitors (methanol, MEG), insulation and best-guess remediation to deal with hydrates. But these methods are reactive rather than proactive, and none provide operators with the one thing they need most in a hydrate event: certainty of location.

However, a better future exists. You don’t have to spend hours – or days – digging for answers in the wrong place after being forced to rely on gut instinct or incomplete and inaccurate data. Instead, precision and trusting the available data should be a standard part of the job. Thankfully, solutions that demonstrate immediate awareness of what is limiting or holding up the pipeline flow exist.

Allowing operators to act fact and restore flow, software systems that pinpoint blockages and obstructions are a welcome innovation in the changing world of asset management. Rather than a seemingly never-ending game in which the workforce burns time and money on risky excavations to still come up empty-handed, up-to-date technologies and software present an alternative where operators can strategically invest time and resources by understanding exactly where blockages occur.

Pipelines speak in frequencies, determined by subtle pressure fluctuations all the way through to abrupt (and sometimes drastic) pressure changes that tell a complete story. Technologies – such as obstruction locators and pre-existing leak detection systems – decipher the story that pipelines are trying to tell through 3D frequency plots and advanced filtering and pattern matching, capturing and analyzing pipeline signals to reveal fresh insights that traditional obstruction and flow assurance methods once missed.

Utilizing decades of data from real-life operations, mistakes made and crises averted have made the development of new analytical tools a reality – tools enhanced by machine learning (ML) and artificial intelligence (AI) functions. With the advantage of ML and AI, advanced and predictive analysis methods have enabled users to dive deeper than ever before into managing pipeline conditions and preventing the accumulation of deposits and obstructions. By curating samples of pressure events and shifts, tests and anomalies to feed platforms and models, technicians have been able to train systems to recognize patterns, eliminate inefficiencies, and transform raw data into proactive action.

By processing huge samples of data (and doing so quickly), users can now access greater insights on asset health and potential risks, leading to more informed decisions regarding maintenance plans and the targeting of obstructions, including tricky-to-identify hydrate plugs. Managing both flow assurance and pipeline integrity with greater accuracy and ease, we are now in a position to maximize efficiency and reduce costs.

New way to pinpoint blockages

AI and ML have both been fundamental to the technologies developed in-house at PipeSense. Applying ultra-high-frequency pressure sampling and advanced machine learning, our team of engineers has created solutions to detect, pinpoint and validate pipeline anomalies and leaks – all with the aim of maximizing efficiency and the service life of a pipeline asset.

PipeScan was designed to accurately locate obstructions inside pipelines, whether hydrate plugs, stuck pigs or closed valves, without invasive inspection.

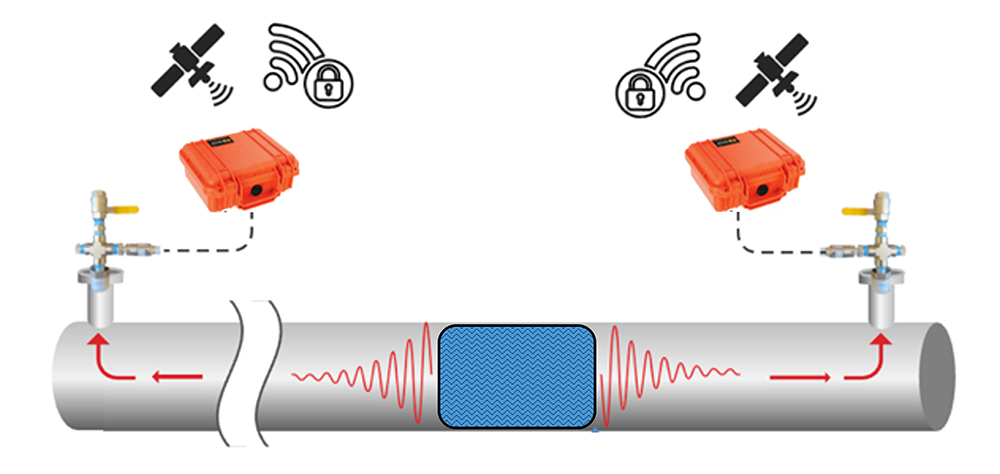

The system leverages three key elements.

- High-frequency pressure monitoring: PipeScan deploys portable field processing units (FPUs) connected to high-speed pressure sensors on the pipeline. These sensors sample pressure at 1,000 times per second, capturing subtle transients in pipeline behavior.

- Pressure pulse induction: By briefly releasing product through a valve and release manifold, PipeScan generates controlled pressure pulses inside the line. These pulses travel through the pipeline until they encounter a blockage, at which point they reflect back toward the sensors.

- Advanced signal analysis: The system accurately time-stamps reflections and calculates distances using the speed of sound in the pipeline medium. By cross-referencing readings from multiple FPUs, PipeScan triangulates the exact location of the obstruction, even distinguishing between single plugs and clusters.

Earlier this year, the functionality of the PipeScan system was on full display to tackle problematic hydrate plugs head-on.

Working with a U.S.-based oil and gas operator, PipeScan was used to address the suspected presence of a hydrate plug within a 12.5-mile segment of a pipeline carrying liquid propane. The pipeline had gone static under winter conditions, with pressure readings suggesting a full blockage.

The operator faced a familiar dilemma: where exactly was the obstruction? Without knowing, crews risked spending days applying heat, depressurization or inhibitor treatments at the wrong locations. That uncertainty risked prolonged downtime, escalating costs, and increasing safety concerns.

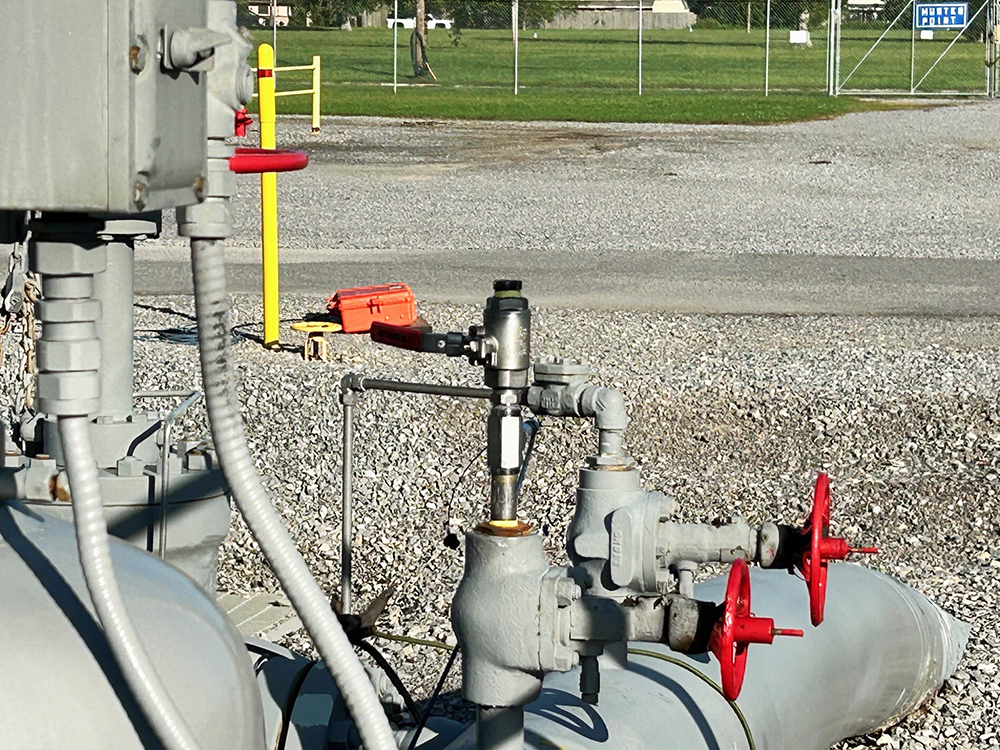

Recognizing the limitations of traditional approaches, the operator contracted PipeSense to deploy PipeScan for rapid hydrate plug location. The company mobilized a single field technician with state-of-the art field processing units to the suspected segment, backed by in-house data analysis experts. Two FPUs were installed at boundary points of interest, connected to a pressure sensor manifold, powered via portable generators, and linked to PipeSense’s analysis platform through Starlink satellite communications.

The testing procedure involved generating controlled two-to-three-second pressure pulses at multiple sites. For each pulse, sensors recorded the reflections returning from the suspected blockage, with tests repeated three times at five-minute intervals to ensure consistency.

Like finding the needle in the haystack, the PipeScan campaign quickly narrowed down the hydrate’s location. Across five test series, the system calculated five potential plug points at distances ranging from 2,200 feet to nearly 29,000 feet from test manifolds.

The results revealed two clusters of blockage reflections. This pattern was consistent with hydrate morphology – diffuse, irregular plugs rather than the sharp reflections typical of mechanical obstructions. Armed with both GPS coordinates and linear distance calculations, the client could now confidently target its remediation efforts, reducing wasted time and unnecessary interventions.

New standard in blockage detection

By deploying PipeScan, the operator transformed an ambiguous hydrate event into a solvable engineering challenge. The benefits included:

- Rapid location intelligence. Instead of days of trial-and-error, the plug’s probable positions were mapped in a single day of testing.

- Reduced downtime. Clear guidance meant remediation efforts could be focused where they mattered most.

- Improved safety. By minimizing guesswork, the risk of uncontrolled releases or pipeline damage was reduced.

- Operational confidence. PipeScan provided not just GPS coordinates but also linear distance references, allowing the operator to validate against its own survey data.

The project was a clear demonstration of how modern analytics and field-deployable technology can turn one of the industry’s most challenging problems into a manageable process.

Hydrate plugs aren’t going away. As pipelines continue to operate in challenging environments – from deepwater to frigid winters – operators will need better tools to fight them. Chemical injection and insulation remain important prevention strategies, but when hydrates do form, location is everything.

PipeSense’s PipeScan has already proven its value not only for hydrate events but also for locating stuck pigs, closed valves, debris and other obstructions that cause uncertainty and downtime. By combining speed, accuracy, and portability, PipeScan is setting a new standard in pipeline blockage detection.

In an industry where every hour of lost production can cost millions, and every uncontrolled release risks lives and the environment, the latest technologies and software platforms provide the clarity operators need. As this case shows, sometimes the difference between frustration and resolution comes down to knowing exactly where to look.

ABOUT THE AUTHOR: Stuart Mitchell is the president and chief technical officer for PipeSense.

Comments